Close search

Published :

/

Published :

/ Posted by : Retch

Posted by : RetchVentilation is a management job that must be done well in modern chicken farming. Maintaining a certain amount of ventilation in the chicken house can keep the air fresh, provide sufficient oxygen for the chicken house, and create a chicken house environment with suitable temperature and humidity for the chickens. It helps that environmental stress triggers the onset of disease.

There is more than one way to ventilate the chicken house. When the seasons change, especially in the cold season, it is necessary to deal with the contradictory relationship between ventilation and warmth. The following is an introduction to the ventilation methods and principles of the chicken house.

Traditional open and semi-open chicken houses generally adopt natural ventilation, and air circulates through floor windows, skylights or ventilation belts and windows. In the high temperature season, the effect of natural ventilation cooling alone is not ideal. In addition, in the early stage of brooding in modern closed chicken houses, ventilation pipes and small ventilation windows are sometimes used for natural ventilation.

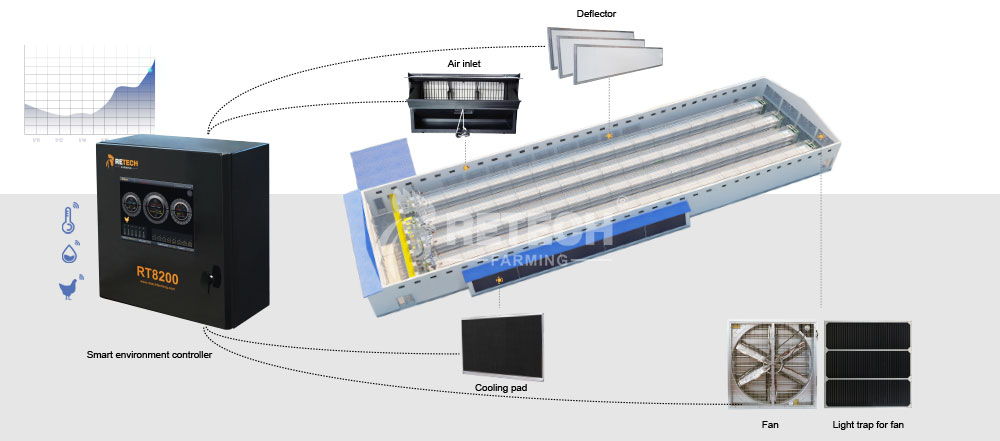

At present, most closed chicken houses adopt longitudinal negative pressure ventilation. The fans are all installed on the gable at one end of the chicken house (generally on the side of the sewage channel) or on the walls on both sides near the gable, and the air inlets are on both sides of the gable and side walls on the other side. On the walls, there are no doors and windows or the doors and windows are closed in other parts of the house, and the air flows along the longitudinal axis of the house.

3. Longitudinal positive pressure ventilation

The fan forces air into the house, and the air outlet is adjusted accordingly so that the amount of air out is slightly less than the amount of air in, creating a slight positive pressure in the house. Air is usually distributed in the house by placing tubes longitudinally equal to the full length of the house, and positive pressure ventilation is sometimes required for full-overlap multi-story houses.

1. Problems prone to occur when seasons change

In spring, the daytime is warmer, but not as hot as summer, and the night is cooler, but not as cold as winter. At this time, we often think that it is neither cold nor hot, and ventilation in this season should be the easiest. In fact, many chicken farms will have the following problems when the seasons change, resulting in the failure to make good use of the ventilation system and induce respiratory diseases in the flock.

First of all, the number of air inlets on the side wall of the chicken house is not enough, so that a proper transitional ventilation system cannot be satisfied. Secondly, the ventilation system is wrongly adopted. When the transitional ventilation system should still be used, it is converted into a longitudinal ventilation system, which causes excessive ventilation to bring stress to the chickens. Then the airtightness of the longitudinal air inlet is poor when it is closed, so the longitudinal ventilation system is used during the day, but the minimum ventilation system cannot be used when it is cold at night, resulting in poor air quality in the house. In addition, the transitional ventilation system cannot be completely an automatic control system, and many random problems will affect the ventilation effect.

2. Minimal ventilation system

When the temperature of the chicken house is at or below the set temperature, we open part of the air inlet, and the operation of the fan is controlled by a fixed clock. Therefore, only by setting the timing cycle can the needs of the chickens be met, thus providing a good environment for the chicken house. air quality.

The air inlet on the side wall is controlled by negative pressure, and the air flow reaches the middle of the roof of the chicken house, which can not only make full use of the heat on the roof, but also prevent the cold wind from blowing directly on the chickens, and at the same time turn on the heating system as needed.

The longitudinal air inlets should be sealed when using the minimum ventilation system, if the longitudinal air inlets are not properly sealed, the minimum ventilation system will not work well. Therefore, when the temperature is high during the day and the vertical ventilation system is used, and the temperature becomes low at night and the minimum ventilation system is required, the vertical air inlet must be sealed tightly. When the temperature of the chicken house is higher than the set temperature, the fan is no longer controlled by a fixed clock, but runs continuously for transitional ventilation.

3.Transitional ventilation system

Transitional ventilation is between minimum ventilation and longitudinal ventilation. It is necessary to increase the number of side wall air inlets. Mixed use of minimum and longitudinal ventilation fans, the air enters the house from the side wall air inlets, so that more air can enter the house , and there is no wind-cooling effect of longitudinal ventilation to avoid stress in the flock. Transition ventilation systems can be used for longer periods before switching to tunnel ventilation.

The transition ventilation system is to open all the side wall air inlets when the temperature of the chicken house is higher than the set temperature, and the fan of the minimum ventilation system is no longer controlled by a fixed clock, but runs continuously. i.e. all air intakes for the minimum ventilation system are open, sometimes partial tunnel ventilation fans can be used.

4.Management of Transition Ventilation

We know that when the temperature of the chicken house is below the set temperature, the minimum ventilation system is used. Only when the house temperature is always above the set temperature can transition ventilation be used. At this time, the air flow in the house increases, and the chickens are easy to lie on the ground. Therefore, we should judge how many machines to turn on based on the performance of the flock. That is to say, it is more necessary to observe the behavior of the flock, and not just look at the temperature measured by the thermometer to manage the ventilation system.

Only switch to tunnel ventilation when birds still appear to be too warm at maximum transition ventilation. Do not switch to longitudinal ventilation just because the temperature measured by the thermometer has exceeded the standard. Otherwise, if it is converted to longitudinal ventilation too early, the flock will be exposed to cold stress and catch a cold, often lying on the ground and unwilling to move, that is, the activity will become poor.

Every time after changing the ventilation setting, as a manager, you should stay in the chicken coop in person, it is best to wait for about 20 minutes, and carefully observe whether the activity of the chickens is better, so as to determine whether the ventilation we set is more reasonable . However, most managers only tell workers to adjust the ventilation system at will based on experience, without continuing to observe the actual performance of the flock. This approach is very passive and undesirable.

In spring and autumn, the daytime temperature is high, and transitional ventilation or longitudinal ventilation is generally required. At night, when the temperature drops, it must be converted to minimum ventilation. In this way, the ventilation system can be switched back and forth. At this time, it is ideal for the chicken house to have automatic control capabilities, but it is very difficult in actual production. Few can achieve automatic control. Therefore, when using minimum ventilation at night, the longitudinal ventilation inlets should be properly sealed, otherwise the minimum ventilation will not work well. At the same time, manage the clock cycle time to ensure good air quality in the house.