Close search

Published :

/

Published :

/ Posted by : Retech

Posted by : RetechWith the development of the poultry raising industry in the Philippines, more and more large-scale farms are turning to intelligent and modern poultry farming solutions. It’s a knotty problem how to deal with the manure for large-scale farm with many buildings.

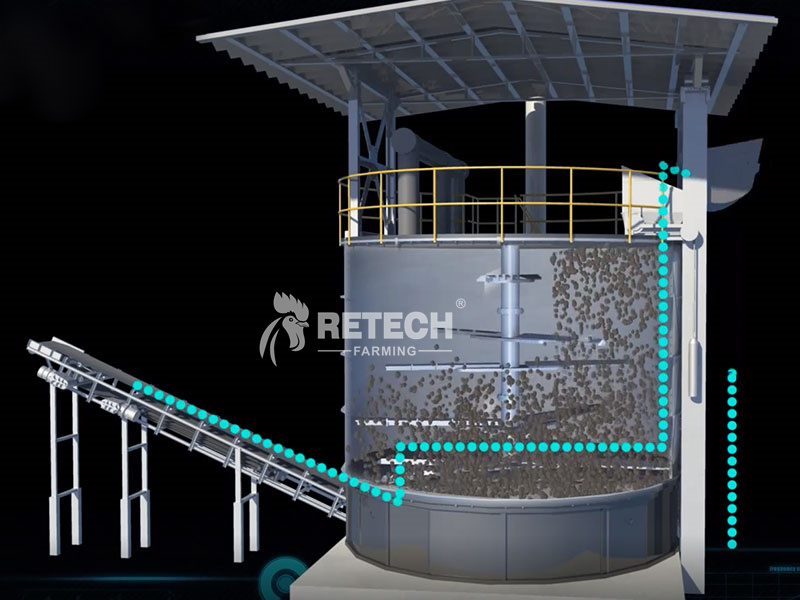

Deep treatment the manure by the energy saving fermentation tank independently developed by RETECH is sustainable agriculture management method.

Is your farm facing any of the following problems?

1. A lot of chicken manure is produced every day,don’t know how to deal with it,cased the accumulation of manure?

2. There is a bad smell in the chicken house, breeding bacteria and flies, which are often complained by neighbors?

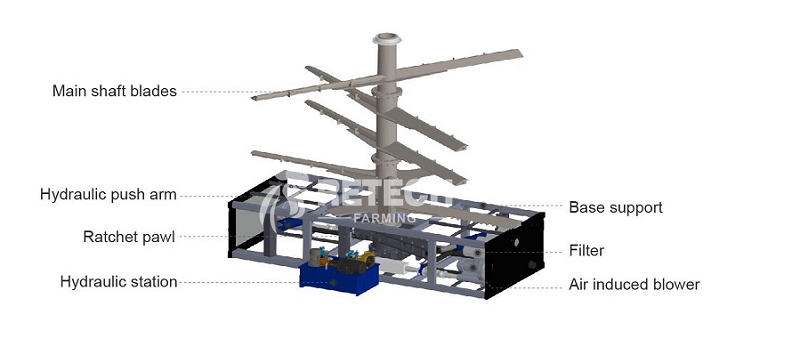

Manure fermentation is a biological process that converts raw poultry manure into a more stable, nutrient-rich product. Make microorganisms multiply rapidly by the aerobic microbial fermentation。At the same time, a large amount of heat is released during the breeding process, which raises the temperature of the tank. 45℃~70℃ further promote the growth and metabolism of microorganisms, while the temperature above 60℃ can kill harmful substances, while meeting the survival conditions of beneficial bacteria, so as to achieve the harmless treatment of livestock and poultry waste. Treated clinker will do directly used as a fertilizer can also be used as a raw material to produce composite organic fertilizer, to ensure the large-scale, green and sustainable development of the farming industry.

Fermented manure with less odour, and converts harmful pathogens into beneficial microbes, making it safer for agricultural use.

Vertical closed manure fermentation tanks are usually more space-efficient, can handle larger volumes and is suitable for large farms.

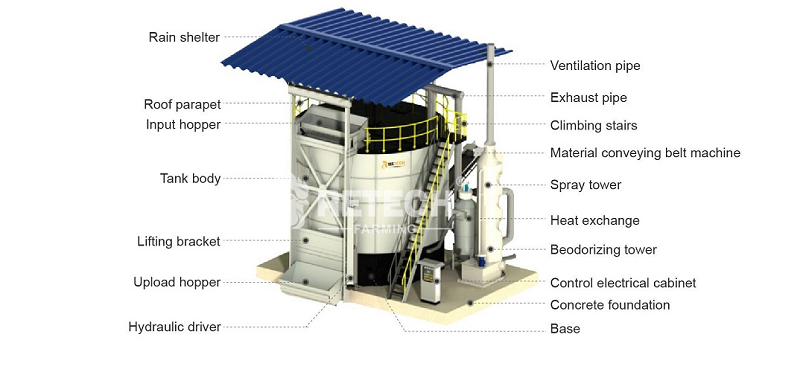

The tank body is fully enclosed, the fermentation process is not affected by the natural environment, so that the production of organic fertilizer can meet the industrial production standards, prevent the exhaust gas generated by fermentation from leaking out, and eliminate secondary pollution.

Factor | Traditional Composting | Fermentation Tanks |

Impact on Environment | Pollutes the land; soil cannot be reused, and high risk of groundwater contamination | Sealed processing ensures no land pollution, protecting the environment. |

Odor & Hygiene | Strong odor, especially in humid or rainy conditions, attracting flies and pests. | High-temperature fermentation eliminates odors, flies, and bacteria. |

Government Compliance | Risk of fines or warnings due to pollution complaints from neighbors. | Eco-friendly solution that meets government environmental standards. |

Processing Time | Requires months to decompose properly. | Fully decomposes manure in 7-10 days, turning waste into organic fertilizer quickly. |

Efficiency & Output | Unstable decomposition, requiring large land space. | Automated process, compact design, and consistent output of fertilizer. |

Labor & Maintenance | Labor-intensive, requires constant turning and monitoring. | Fully automatic operation, reducing labor costs. |

1.Environmental Pollution – Burying chicken manure contaminates the soil, making the land unusable over time.

2.Unbearable Odor & Pests – Open composting areas attract flies, rodents, and emit a strong stench—especially in humid or rainy conditions.

3.Slow & Inefficient Decomposition – Traditional methods take months to fully break down manure, delaying fertilizer production.

4.Regulatory & neighbor Complaints – Improper waste handling can lead to warnings from environmental authorities and complaints from neighbors.

1.Enclosed & Pollution-Free – Prevents land contamination and protects surrounding water sources.

2.Odor & Pest Control – Fully sealed design eliminates odors and keeps pests away.

3.Fast & Efficient Fermentation – Converts manure into high-quality organic fertilizer in just 7–10 days.

4.High-Temperature Sterilization – Kills harmful bacteria, insect eggs, and weed seeds, ensuring safe and nutrient-rich fertilizer.

5.Government Compliance & Sustainability – Eco-friendly waste management aligns with environmental regulations and supports green farming.

Upgrade to Fermentation Tank Technology & Maximize Your Farm’s Potential!

The fermented manure contains more nutrients such as nitrogen, phosphorus and potassium, and is an excellent organic fertilizer. This can improve crop yields and soil health.

The fermentation process can significantly reduce harmful bacteria and pathogens, making manure safer to apply to crops and reducing health risks.

By converting waste into a valuable resource, farmers can save on fertilizer costs and potentially generate additional income by selling fermented products.

During fermentation, the internal temperature of Retech's energy-saving fermentation tank can reach over 60 degrees, which can effectively kill pathogens, insect eggs and plant seeds, etc. A biological deodorization tower is set up, and the waste gas generated during the fermentation process is treated by the deodorization tower and discharged through the exhaust pipe after passing through the filtering device, which can effectively reduce the content of harmful gases.

We already have customers in the Philippines using energy-saving fermentation tanks, and they are very satisfied. If you want to visit our fermentation tank project, please contact me!

As the poultry farming market in the Philippines grows, large farms are paying more and more attention to the development of sustainable agriculture. Investing in energy-saving fermentation tanks is a good choice for efficient treatment of farm manure. Advanced fermentation technology and automated monitoring systems enable large farms to reduce energy consumption, improve manure treatment efficiency, and make positive contributions to the environment!

We provide modern poultry farming solutions, one-stop farming services including chicken farming equipment, steel structure houses, farm supporting equipment, contact me for more information on energy-saving fermentation tanks!

Website: www.retechfarming.com

Facebook: @retechfarmingchickencage 100k Followers