Close search

Published :

/

Published :

/ Posted by : Retch

Posted by : RetchPoultry production has taken an important part in the world’s agriculture industry in recent years. It is expected that the global poultry meat output would reach 1,942 million tons in 2010, The compound annual growth rates of chicken meat and egg markets are expected to increase significantly during the next ten years 2020-2030, according to the latest research from experts. The report forecasts that chicken meat consumption worldwide will rise 3.0%, reaching 1.6 billion metric tons in 2025. In addition, it predicts that global egg demand will see an average annual increase of 5.5% over the same period, rising to 984 million dozen eggs in 2025.

As you can see, It's a huge increase on the demand side, but it's another story on the supply side, as the production efficiency in most developing countries like Africa, South Asia is still very low, and there is plenty of room for improvement.

So what could be possible reasons to cause the low efficiency in the poultry production process?

There are many factors that can affect the production efficiency. One of them is the lack of a proper ventilation system. Ventilation systems play an essential role in maintaining good air quality inside poultry houses. if you don't have a good design for a ventilation system when you build the poultry house, it might cause serious issues for your chicken farm:

which results in the accumulation of moisture and dust particles inside the poultry houses. This causes respiratory problems among birds such as coughing, sneezing, and breathing difficulties. Furthermore, the accumulated moisture and dust particles inside poultry houses also leads to increased risk of diseases such as Newcastle disease, infectious bronchitis, and fowl cholera.

Ventilation system will help to control the climate condition inside the poultry house, For some area in the world with extreme weather conditions in the tropical region like Africa or South Asia, the outside temperature is very high, and chickens are highly sensitive to changes in temperature. Hot weather causes them to lose water, leading to dehydration and reduced appetite. They also stop producing enough enzymes needed to metabolize nutrients properly. Birds can die within hours after being exposed to extreme heat.

Without Ventilation system, the heat stress could be a huge problem in poultry production, especially in the production and processing of chicken meat and eggs. When chickens are exposed to temperatures higher than 26.7 ° C (79.4 ° F) for prolonged periods, they start panting and may die if not given water. High ambient temperatures also reduce the amount of oxygen available to the body, causing respiratory distress. Birds raised in an enclosed space like cage or coop, they are particularly easier to get heat stress because they cannot escape the heat through movement.

Traditionally, most poultry chicken farmers when they started up poultry business with small capacity, they will use the Natural ventilation with opened house., it has been identified with the tropical regions for its simplicity, economical implications and ease of management of heat generation within the buildings through natural ventilation. The advantage of natural venting is the low investment due the use of natural resources. . Natural ventilation systems have fallen out of favor because they require constant attention and manual intervention.however, since it's totally manual operation, it becomes less popular due to the disadvantages of manual control and limited capacity.it is also prone to invasion of insect, rodents and other small predators that disrupts the production performance.

Natural ventilation might work well for start-up small capacity farm, but when you expand the business to a much larger scale, Tunnel ventilation would be a better fit and the ultimate solution for modern large-capacity poultry chicken farms.

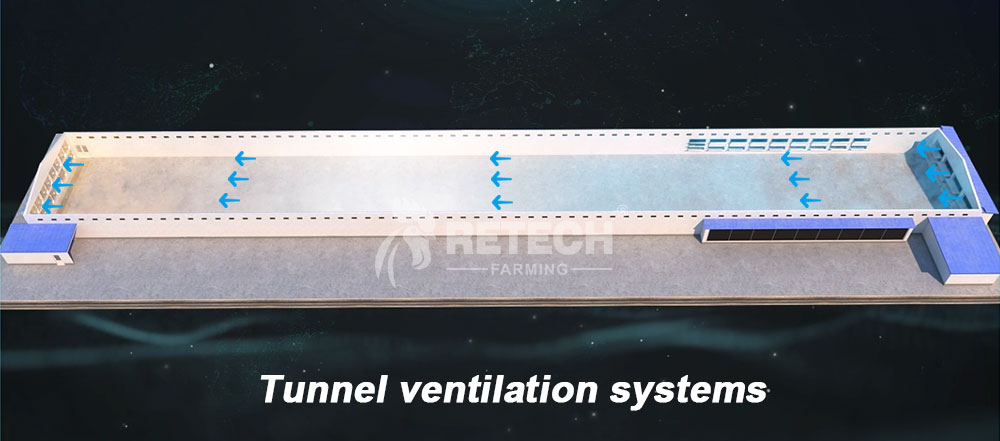

Tunnel ventilation is a form of mechanical ventilation where fresh air enters from one end of the building and exhausts at the opposite end. It is used primarily in large commercial poultry operations. In this type of ventilation, the air flows through a series of tunnels located throughout the building. These tunnels are usually made of concrete or metal pipes, Large exhaust fans are installed on one end of the house and large curtains are installed on the opposite end wall. Air is pulled from one end of the house to another in a minute or less, flushing excess heat from the house while providing velocity over the birds of per minute or greater, helping pull heat from their bodies. For maximum ventilation, ventilation is often used where both ends of the building are ventilated. This allows blowing the air into the house at high speeds during very hot days. High speed provides a wind chill affect, which gives the chickens an enjoyable feeling temperature.

Tunnel ventilation systems is gradullay becoming one of the basic standards in poultry chicken business around the globe. So what are benefits of this tunnel ventilation system? Here are few advantage that will help you understand why tunnel ventilation is so important in the poultry chicken industry:

Improved weight gain and better feed conversion, , high velocity air flow created by tunnel ventilation cools the birds more effectively than conventional systems.

The pressure difference between the internal and external environment determines the entry speed of fresh air, A good mechanical ventilation system needs to exchange the air quickly so chickens will have access to more fresh air inside house.

Ammonia is produced as a result of bacteria growth in manure. Ammonia can cause respiratory problems in chickens. Tunnel ventilation helps reduce ammonia levels in the house.

Tunnel ventilation systems are designed to provide maximum airflow while minimizing temperature variation within the shed. They do this by creating a large volume of air flow across the entire surface area of the building. This allows heated air to rise, cool down, and move out of the building. In addition, tunnel ventilation systems allow cold air to enter the building, thus reducing the amount of energy required to heat the space.

A number of studies have shown that tunnel ventilation systems reduce the mortality rates of broiler chickens. For example, one study found that tunnel ventilation systems increased the average daily gain of broilers by 2.5% compared to conventional ventilation systems, to help you improve productivity at your farm and increase the profitability for your investment.

So if you do want to expand your poultry business to set up a large capacity commercial poultry farm, this tunnel ventilation system is important and necessary.It is also a good idea to consult with a professional who has experience designing tunnel ventilation systems. While the concept is relatively simple, to ensure you are getting the most efficiency and benefit from a tunnel ventilation system, to consult someone who knows what to look for. Two significant considerations are your air velocity and air exchange rate. Ensure the system you are adding is getting enough wind across your birds.

Retech has been exploring and studying the poultry industry for over 30 years, we’re very familiar with your local market, helped many chicken farmers to achieve great success by renovating their farms and upgrading their equipment, with more than 30 years of production experience, we can design and manufacture both chicken house and chicken cage based on your need and requirement, we can provide clients with automatic layer cage, broiler cage, and pullet cage, with best quality raw material, state of art of technology, competitive price, good service before/after the sale.

So if you looking for a poultry chicken business opportunity, and if you want to start your own Poultry Chicken Business, pls feel free to give us a call, would be more than happy to help you!

Facebook: @retechfarmingchickencage 100k Followers

Whatsapp: +8618561818859

Email: info@retechfarming.com