Close search

Published :

/

Published :

/ Posted by : Retech

Posted by : RetechThe poultry farming industry is experiencing rapid growth globally, driven by the increasing demand for high-quality protein. According to market reports, the global poultry meat market is expected to continue expanding due to population growth, urbanization, and rising consumer preference for chicken meat. However, modern poultry farmers face challenges such as labor costs, biosecurity concerns, waste management, and the need for efficient production systems.

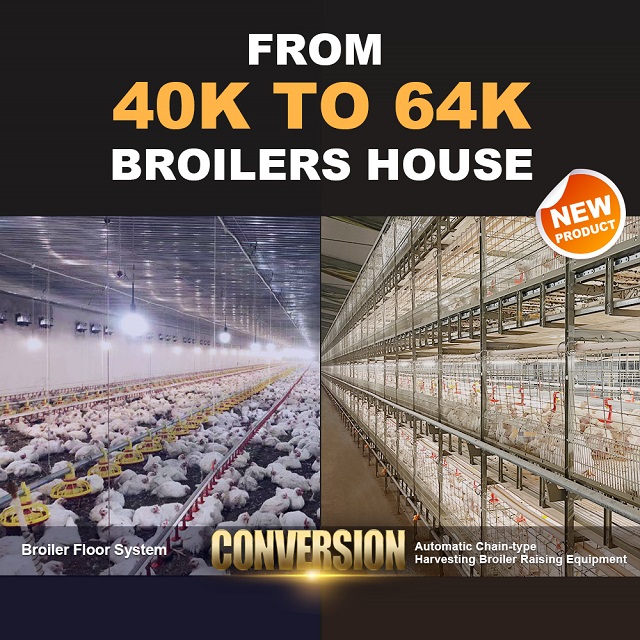

To meet these demands, the industry is shifting towards automated and high-efficiency farming equipment that ensures productivity, animal welfare, and sustainability. One of the most advanced solutions in this field is Retech's chain-type broiler raising equipment, which optimizes the farming process and helps maximize profits.

A well-designed broiler cage system is essential for maximizing space utilization and increasing the survival rate of chickens. Retech’s chain-type broiler raising equipment offers the following advantages:

· 2 to 4 tiers battery cage system allows 2–4 times higher capacity compared to floor-type systems.

· Maximizes vertical space, reducing land usage and energy costs for heating or cooling.

· Made from Q235 high-quality steel with 275g/m² hot-dip galvanized coating for superior corrosion resistance.

· Ensures a 20-year service life, reducing long-term maintenance costs.

· Each cage holds 135 birds (1.8kg slaughter weight), ensuring even feed distribution and easy observation of bird health.

· 334cm² chicken area per bird maximizes feeding space, leading to higher feed utilization.

· 334cm² living space per bird ensures better comfort and movement.

· Optimized raising environment improves feed conversion ratio (FCR) and overall broiler growth efficiency.

· Ensures uniform feed distribution, reducing waste and improving feed conversion rates.

· Reduces labor costs by automating the feeding process.

· Uses a nipple drinking system to provide clean and continuous water supply.

· Reduces the risk of water contamination and disease transmission.

Efficient waste management is essential for farm hygiene and environmental compliance. Retech’s automatic manure cleaning system helps:

· Remove manure efficiently to reduce ammonia levels and odor.

· Improve the overall health of the chickens by minimizing disease risks.

· Treamlines the collection process, reducing labor intensity.

· Minimizes stress on birds, leading to better meat quality.

According to the chicken needs and actual temperature, the RT8200 smart controller automatic controls the environmental equipment to maintain a comfortable indoor environment. Intelligent technology replaces labor, reducing the workload of operators and the dependence on technicians.

· Automates feeding, drinking, manure removal, and climate control, reducing labor dependency.

· Maximizes space utilization, allowing for higher stocking density with better growth rates.

· Uses energy-saving fermentation tanks for eco-friendly manure management.

· Minimizes pollution and ensures sustainable poultry farming.

· Durable materials extend equipment lifespan, reducing maintenance costs.

· Increases broiler productivity, leading to higher profits.

As the global demand for poultry meat continues to rise, adopting modern equipment like Retech’s chain-type broiler raising system is key to achieving higher efficiency, lower costs, and sustainable production. Whether you are an experienced poultry farmer or new to the industry, investing in automated broiler farming solutions will help you stay ahead in the competitive market.

Interested in upgrading your poultry farm? Contact Retech today for expert consultation and tailored solutions!

Website: www.retechfarming.com

Facebook: @retechfarmingchickencage 100k Followers

Whatsapp: +8618561818859

Email: info@retechfarming.com

1. How to plan broiler house construction?

2. What conditions are needed to raise broiler chickens?

3.