Close search

Published :

/

Published :

/ Posted by : Retech

Posted by : RetechThe introduction of tunnel ventilation in poultry houses is an effective way to improve the health and performance of birds in a variety of climates. By moving air out of the top floor, rather than just circulating it around the perimeter, it creates a steady flow of fresh air and better control of climate conditions throughout the shed. This is great for poultry production as it results in healthier and more comfortable flocks which in turn helps to optimize feed conversion, maximize body weight and ultimately increase profits.

So how does the ventilation system of the chicken coop work?

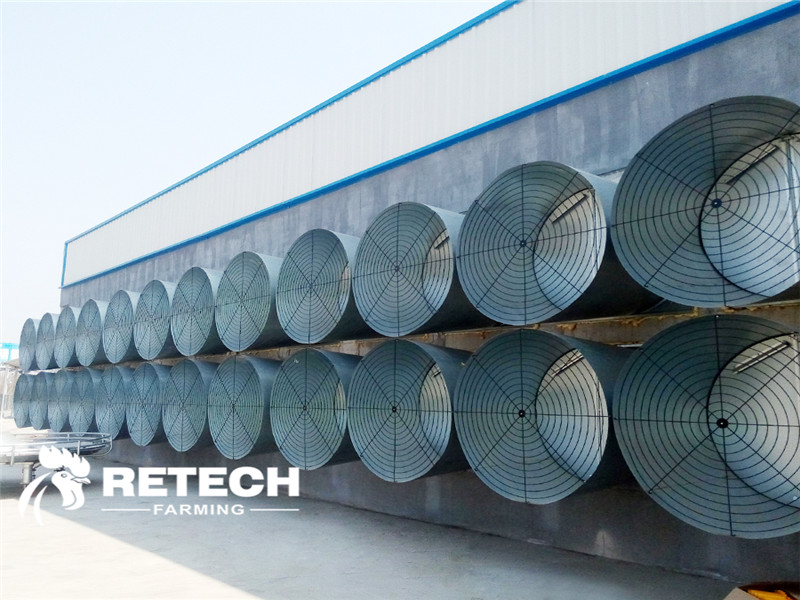

A tunnel ventilation system works by taking in fresh air from outside the shed and distributing it evenly throughout the house. This is achieved by using a fan to create a vacuum in the roof, which then draws in fresh air from outside. The air is then pushed through ducts running the entire length of the shed and distributed through vents located in each bay. It is important to ensure that the desired airflow rate is maintained in order to create the best conditions for the birds and this can be done using a controller which monitors and adjusts the fan speed as needed.

Allows air to move through the shed at a constant, high velocity while supplying fresh air at the floor. This helps maintain optimal levels of temperature and humidity, even during periods of extreme heat which, if left unchecked, can be disastrous for bird performance and mortality.

This helps keep the birds comfortable and healthy, which in turn improves feed efficiency and weight gain.

The efficiency of the tunnel ventilation system is further enhanced by its ability to reduce heat loss and save energy. By controlling the air flow rate, it helps to maintain a stable temperature inside the shed, thereby reducing energy consumption. This means fewer resources are spent on keeping the birds comfortable and healthy, helping poultry farmers save on electricity bills. Tunnel ventilation systems also help create an environment free of dust, odors and disease-causing pathogens, thereby reducing the risk of disease outbreaks in the flock.

Not only does this negatively impact the health of the birds, it also increases labor costs due to the regular cleaning requirements. All in all, this makes tunnel ventilation an ideal solution for producers looking to boost the health and performance of their flocks while controlling costs as well as hot weather or other challenging environmental conditions.

Proper ventilation helps reduce heat and humidity levels and provides adequate air circulation to reduce disease risk. Additionally, it helps prevent ammonia from manure and other materials in the house. Reduce disease problems in chickens.

The best type of ventilation system for a chicken house is one that allows fresh air to be drawn in while still maintaining an appropriate temperature level. This is made possible by exhaust fans and air intakes located near the roofline. Vents should be adjustable so they can be opened or closed depending on the weather outside. Additionally, any windows or doors should be screened to keep pests out.

Retech Farming has been exploring and studying the poultry industry for over 30 years, we’re very familiar with your local market, helped many chicken farmers to achieve great success by renovating their farms and upgrading their equipment, with more than 30 years of production experience, we can design and manufacture both chicken house and chicken cage based on your need and requirement, we can provide clients with automatic layer cage, broiler cage, and pullet cage, with best quality raw material, state of art of technology, competitive price, good service before/after the sale.

So if you looking for a Poultry chicken business opportunity, and if you want to start your own Poultry Chicken Business, pls feel free to give us a call, would be more than happy to help you!

Website: www.retechfarming.com

Facebook: @retechfarmingchickencage 100k Followers